3D Printing Shelved

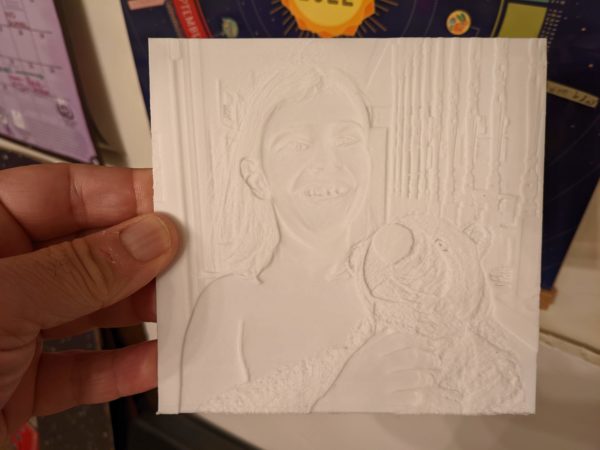

A friend lent me a 3d printer for many months. It was frustrating, frustrating, fun, and frustrating. I’m giving it back to him. It’s an Ender 3 Pro with a Volcano Hot End from Matter Hackers.

Key issues for giving up were:

– layer adhesion (parts are always weak in one plane)

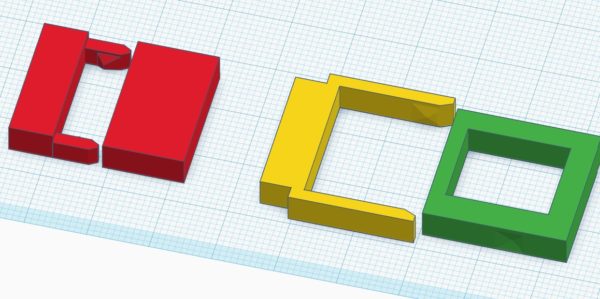

– unsolvable elephant foot problems

– poor dimensional adherence (pegs never quite fit holes, tabs never quite fit slots, etc. the new deburring tool helps some…)

– general strength of materials (I could switch to other materials but I haven’t mastered PLA yet!)

– an unsolved problem with filament occasionally jamming in the hot end

– the challenge of trying to fix any problem that takes 8+ hours to manifest, which is all of them!

– related to the last item, I feel like I haven’t learned anything after all my efforts. Solving each problem has been “fiddle with it until it works, now DON’T TOUCH IT!!! because no one knows why it works or doesn’t. But I’ve GOT to touch it to do anything but a beginner project.

– related to the same, there’s a zillion settings on Cura and no intelligent way to manage them. This becomes critical when you want to be able to change something to either fix or improve a setting. My 3d printer guru friend now devotes one of his 3D printers to a single type of filament (TPU) because he got it working and now he doesn’t dare touch it.

– Speed. Overnight prints are tolerable, 20 hour prints are okish. 50 hour prints? 500 hour prints? Blargh. Subjectively it’d be more tolerable if it were in a soundproofed room, and I was able to reliably make stuff, but the speed seriously limits production capabilities.

When I asked experienced friends for help, they didn’t have solutions to these issues.

I asked one friend about layer adhesion. He said, “oh, no problem, I just print in a different orientation.” I replied, “Yeah, but… so that big piece you showed me a minute ago, if you held it up and tried to pull it apart in the other directi…. ooo, it broke! Yeah, sorry.”

A maker acquaintance, Nick Anastasia reported to me on Facebook when I asked about teaching using 3D printers : (take note of all the pitfalls he reports)

I echo what I’ve seen from others so far. 3D printers are fiddly, even the high end ones. Figure out how much time you can budget towards both the instructor(s) getting super familiar with the ins and outs of the machine and having time to maintain them. This will always take twice as long as you think.

I’ve worked with middle school and high school kids on Creality Ender 3 printers which are super cheap and when they’re setup right they work well enough but can get out of wack in the blink of an eye. My strategy with them has been to have one or more hot spares ready to go. If a print fails rather than debug it on the spot just start it an another machine.

With high school students I was working in a robotics class so I turned tuning and adjusting the machines into mini mechanics and control software lessons. If you can fit that into your lesson planning and the students ability and interested allows go for it. Encourage tinkering and if you’re using super cheap printers they’re not going to break something particularly expensive if they mess up.

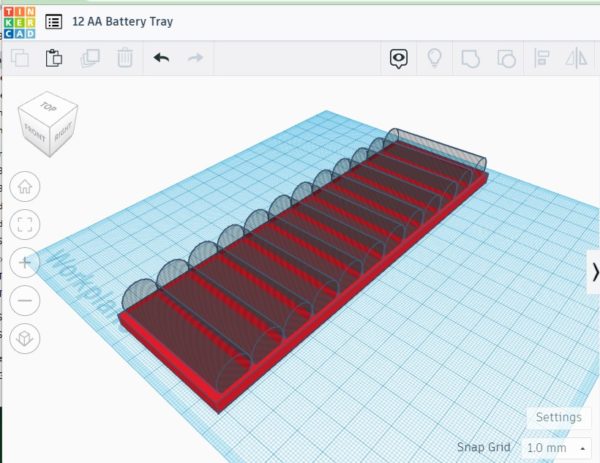

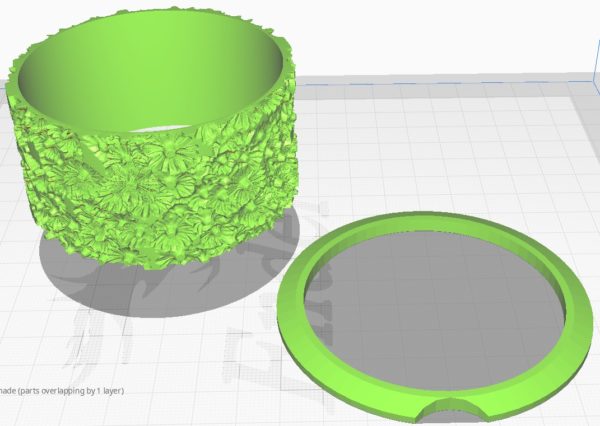

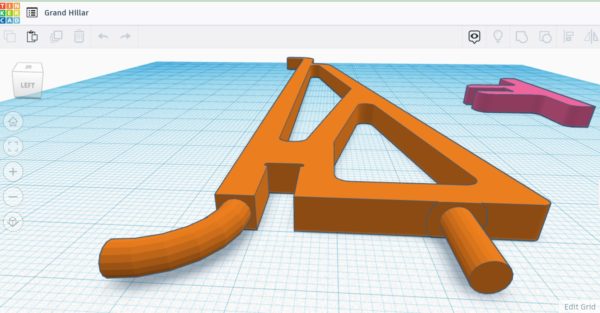

As for 3d design I start all my kids programs on tinkerCAD. It’s the quickest way I know to go from zero to 3D design in under 30 minutes. If kids are really into it then you could try to introduce more complex CAD but they will probably figure out the limitations of tinkerCAD and work around them to get the more complex shapes they want anyway.

Happy to be a sounding board for ideas.

Christine Mytko, “I agree with Nick Anastasia 100%”

My friend Tim Aidley reported similar challenges:

So a big thing about FDM 3D printers is that they still require a lot of handholding and fiddling with to get working well. The Prusas are very good in that in general they are set up very well out of the box, and are fairly reliable. However, you are likely to still get prints that fail partway through, or prints that fail to adhere to the bed etc.

It’s vitally important that whoever runs it knows how to fix these fairly common problems, otherwise you’re likely to end up with a bunch of machines that don’t really work in fairly short order.

I think the suggestion to have several identical printers is a good one. At the makerspace at my previous employer, there were for a while three 3d printers, all of which were different, and it was much too easy to accidentally use the slicing settings for the wrong printer, which would almost always screw up your print and had a fairly good chance of screwing up the printer.

Another thing about these printers is that they’re pretty stupid. The slicer program converts your 3d object in to a set of gcode instructions that the printer blindly executes – so on many printers it’s very possible to try and force the print head through the print bed if things are incorrectly calibrated. I have a printer with a nice scratch on the print bed from just such a thing happening, so you would need to have processes in place that would try and prevent such a thing from happening.

My friend Luke says:

working a 3d printer or a milling machine is a real skill. It is basically a tradesman skill job, specialized and worth having students learn. Like most useful skills, there is probably a fair bit of frustration as you go up the learning curve

Meredith said:

Huh. My ultimaker 2+ is an absolute work horse, and has been for 8+ years. All of my major issues were of my own making- not following basic upkeep, usually. My Form 3L’s main issue is that it’s on an unsteady shelf and I have to re-level it all the time, which I keep a steady supply of magic:the gathering cards for.

Having set up a few labs in my time, ultimately you have to know the difference between a project and a tool. The cheaper 3D printers can be projects in of themselves, while ones more consumer or prosumer oriented are tools. It’s also just a skill set and learning curve- adopting a new technology is. Even impact drivers have them.

So, it’s possible to use a 3D printer as a tool and not a project unto itself. I just haven’t gotten there.